Fengxing Intelligent Freeze-drying Production Line Put into Production

Number of views: 1 Source: Fengxing Intelligent Release Time: 2025-10-20

Recently, Shandong Fengxing Intelligent Technology Co., Ltd. (hereinafter referred to as "Fengxing Intelligent") has achieved significant results in the technical transformation project. Eight new intelligent freeze-drying production lines and supporting facilities have been officially installed and commissioned and put into production smoothly. This technological transformation has realized the automatic upgrading, green transformation and intelligent empowerment of the production process, which will not only greatly enhance the core competitiveness of enterprises, but also inject strong momentum into the high-quality development of the food industry.

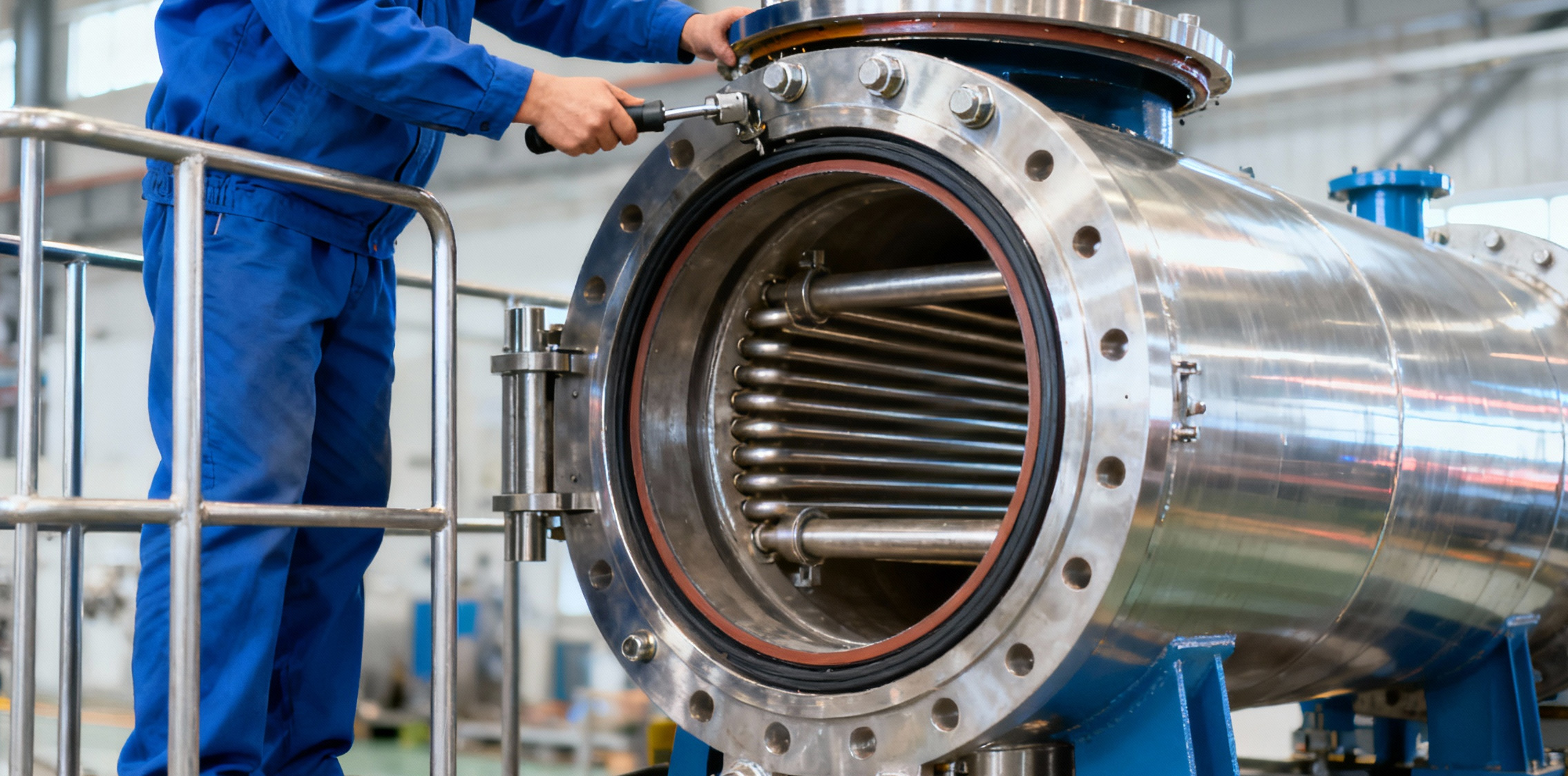

Entering Fengxing's intelligent modern production workshop, a busy and orderly production scene came into view: the neatly arranged brand-new freeze-drying equipment was running at high speed, workers in standard tooling only needed to monitor and operate in key links, and the processes of raw material pretreatment, freezing, vacuum drying, slitting and loading were seamlessly connected through automatic assembly lines. According to the production manager of the enterprise, the newly put into production of freeze-drying production line has completely changed the previous manual and semi-automatic production mode, and achieved a double breakthrough in energy saving and consumption reduction and capacity improvement.

This technical reform is the strategic initiative of the front line intelligent focus on industrial upgrading, the core around the equipment intelligence and energy green two major directions. In terms of equipment upgrading, the enterprise completely eliminated the old production equipment, introduced advanced freeze-drying furnace, IQF flow bed freezer and low-temperature freezer and other automation equipment, with domestic industrial control software and data analysis platform, to achieve accurate monitoring and intelligent control of the whole production process. "After the intelligent upgrade, the production efficiency and product qualification rate have been significantly improved, and the labor cost has also been effectively reduced, which is a radical change for enterprises."

Green environmental protection is another highlight of the technical reform. The project specially carried out green transformation of the boiler room, upgrading the original 22-ton and 12-ton coal-fired boilers to chain grate biomass pellet boilers to reduce pollutant emissions from the source. At the same time, the traditional liquid ammonia refrigeration system is eliminated, the safer and more environmentally friendly Freon refrigerant is adopted, and the variable frequency refrigeration compressor with automatic load adjustment function is equipped. While ensuring production safety, the energy utilization efficiency is greatly improved, and the environmental protection standard is fully achieved. Requirements.

It is worth noting that the project adheres to the principle of "localization priority", and the core production equipment, control system and software platform are given priority to domestic solutions, which provides strong support for the domestic substitution process of China's freeze-dried equipment manufacturing industry on the basis of ensuring data security and independent control of technology. It is estimated that after the completion of the technological transformation, the annual production capacity of Fengxing intelligent freeze-dried food will be increased by 1000 tons, and the production standard will be in line with the international advanced level, laying a solid foundation for expanding the high-end market at home and abroad.

The dividends of industrial upgrading are gradually radiating to the surrounding areas. It is understood that after the new production line is put into operation, a number of new jobs will be created. At the same time, by driving the procurement of local fruits and vegetables and agricultural raw materials, the channels for farmers to increase their income will be further broadened, and a virtuous circle of "enterprise efficiency, people's livelihood benefits, and industrial upgrading" will be formed. The successful commissioning of the Fengxing intelligent freeze-drying production line has set a benchmark for the transformation and upgrading of the regional food industry, and will help the development zone to build a more competitive food industry cluster.

At present, freeze-drying technology has been widely used in the food industry by virtue of its advantages of retaining the nutrition and flavor of food materials to the maximum extent, and the market demand continues to grow. Industry insiders pointed out that the technological transformation practice of Fengxing Intelligence not only enhances the company's own market competitiveness, but also demonstrates the clear path for my country's food processing companies to achieve high-quality development through intelligent and green transformation, and provides valuable experience for industry development.