Snack Food Processing Solutions

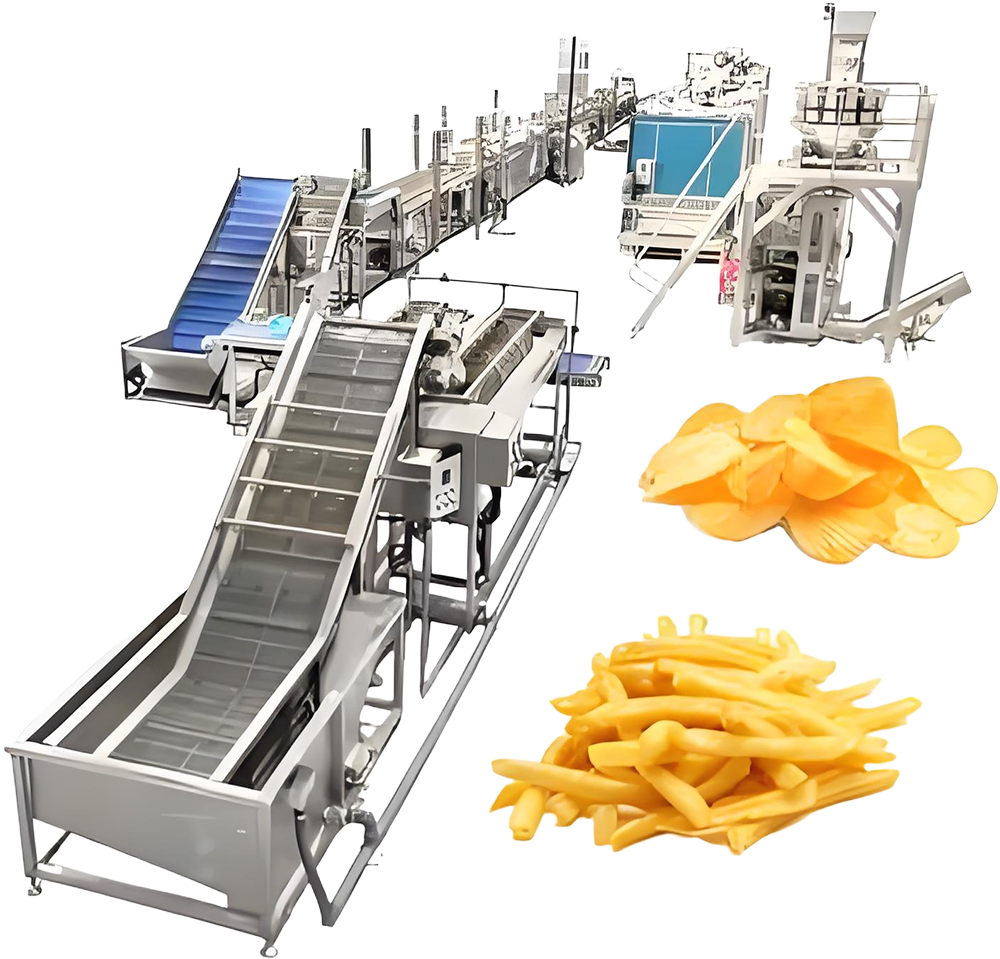

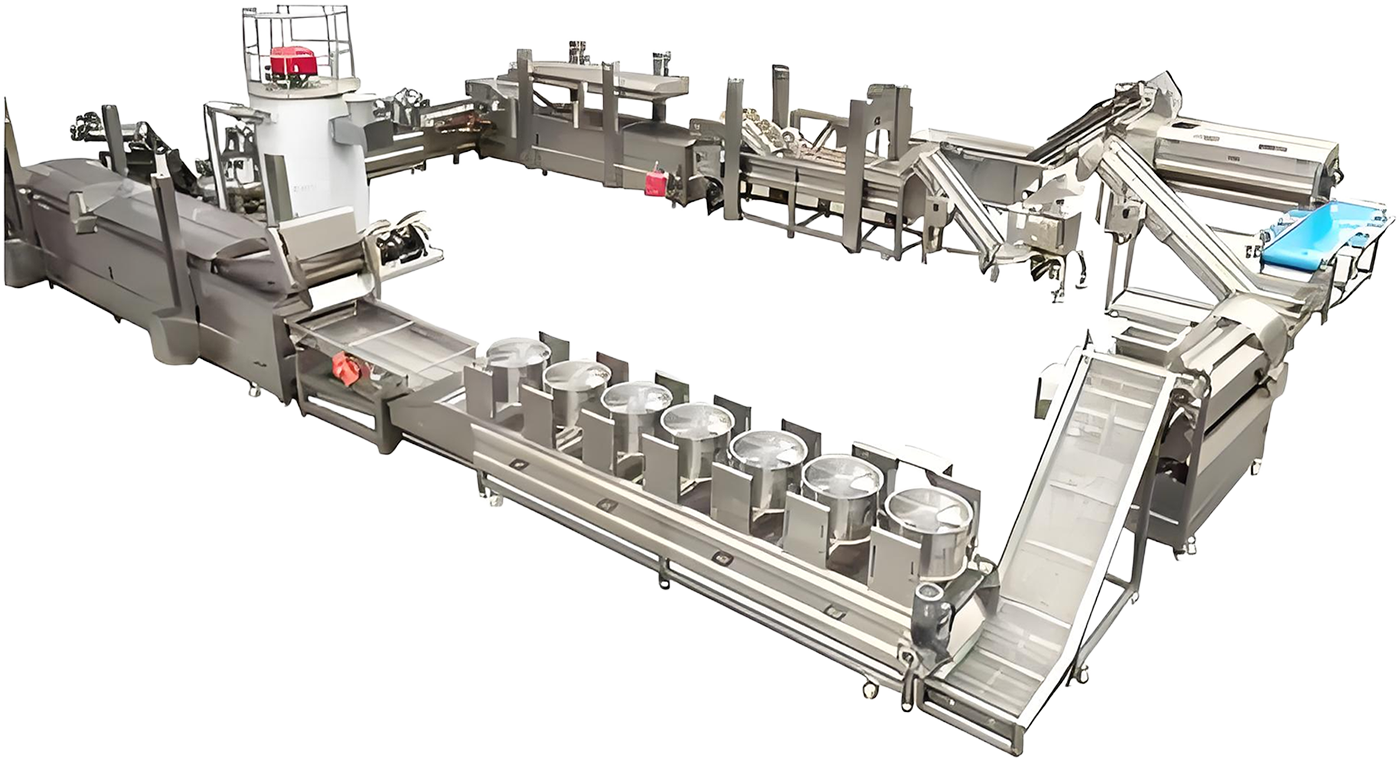

Leisure food processing is based on high-quality raw materials such as nuts, fruits and vegetables, grains, etc. Through diversified process upgrades such as baking, puffing, freeze-drying, etc., and combined with intelligent parameter control and full-chain quality control, the integrated production from raw material screening to packaging, storage and transportation is realized, so as to efficiently adapt to the demand of healthy, multi-category and fast iteration snack market.

Fruit and vegetable processing and freeze-drying solutions

Build a full-chain processing solution from fresh fruits and vegetables to freeze-dried finished products, integrate process design, equipment selection and technical support, take into account production efficiency, product taste and nutrition retention, and meet diversified market needs.

about us

About Us

Shandong Fengxing Intelligent Technology Co., Ltd.It is an intelligent equipment R & D and manufacturing enterprise focusing on the field of food processing. It is deeply engaged in the innovation and application of automation equipment in the whole process of food production. It is committed to providing efficient and stable intelligent production solutions for food processing enterprises, helping the industry to transform from "traditional manufacturing" to "AI intelligent intelligent manufacturing", which is in line with the intelligent and green development trend of the national food machinery industry.

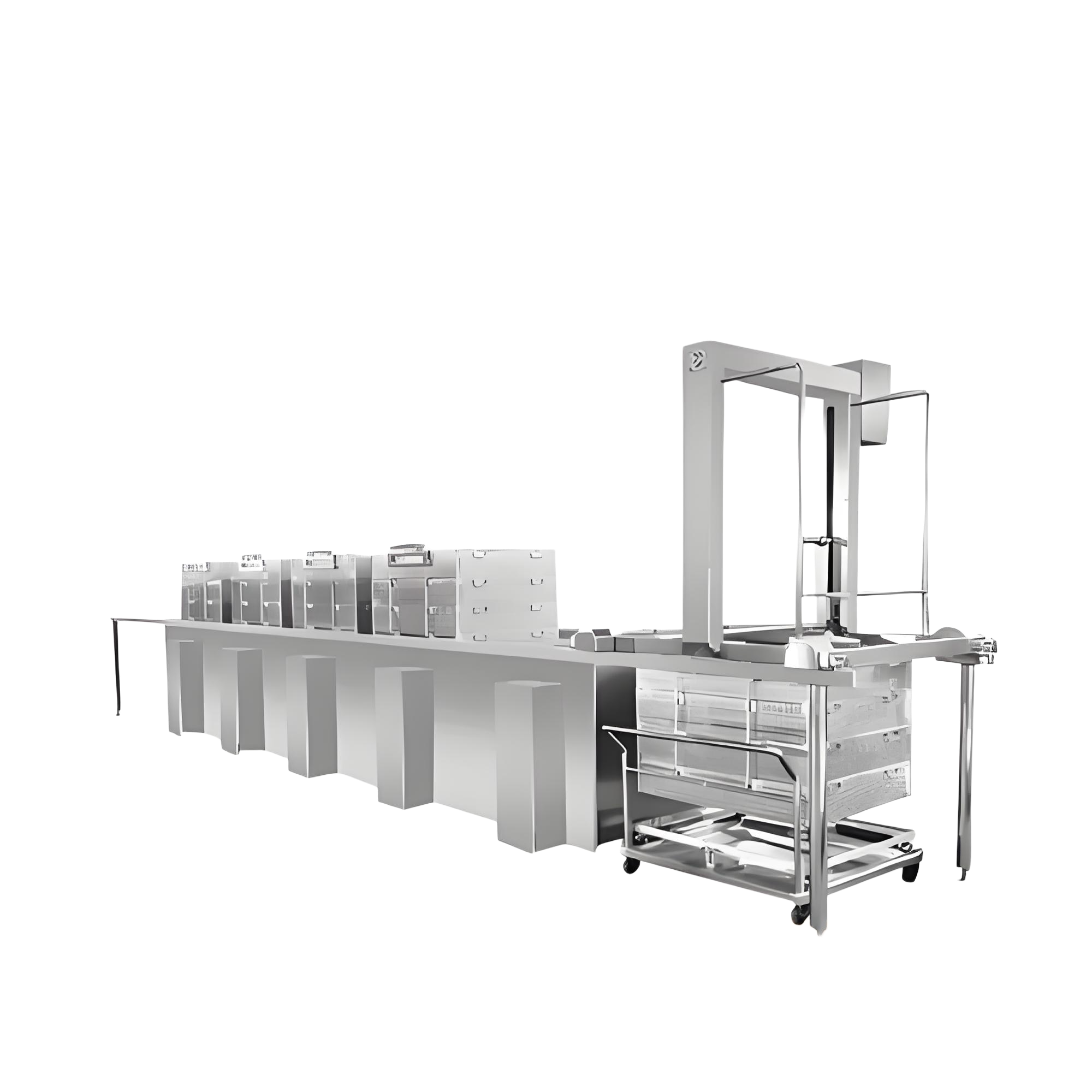

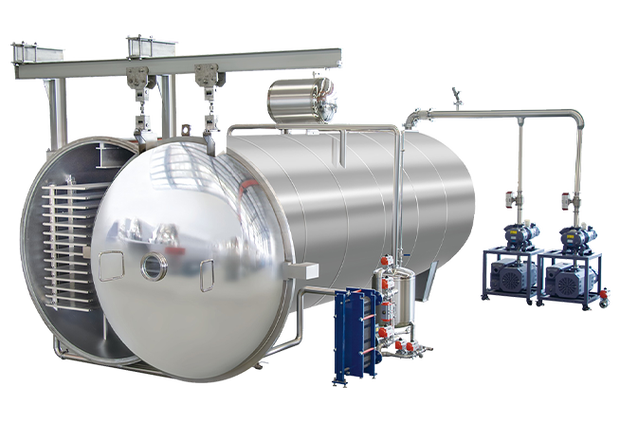

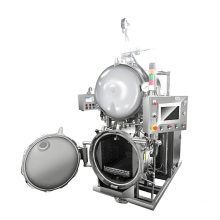

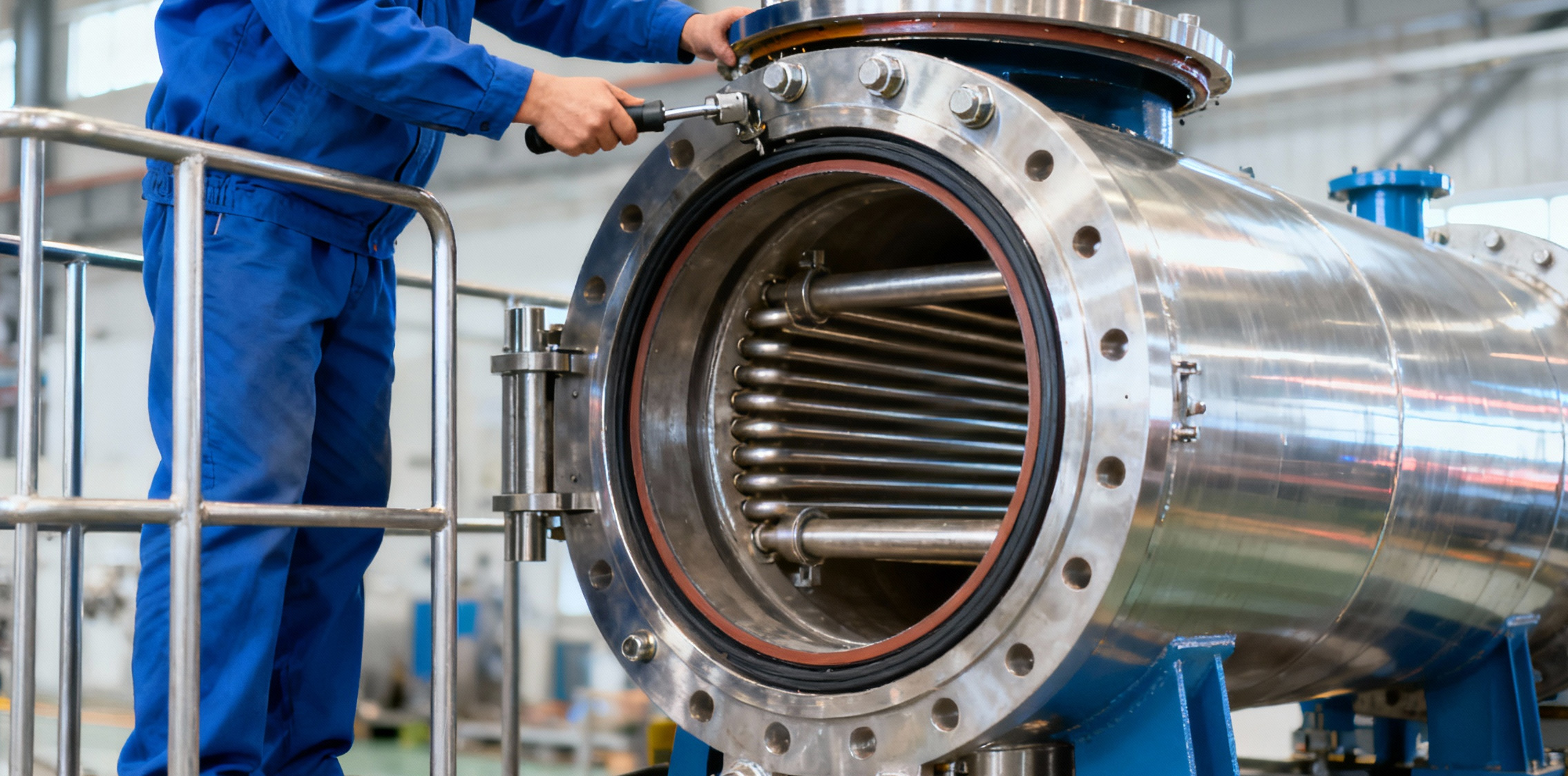

With a deep understanding of food processing technology, the company has created a core product matrix covering key links such as food pretreatment, processing and drying. Its main products include: honeycomb continuous steaming pot, differential pressure extruder, freeze dryer, blanching pot, frying machine, cleaning air dry line, etc. These equipment can be widely adapted to snack foods, pet foods, pre-made vegetables, fruit and vegetable processing and freeze-drying, puffing, meat products and other segments, providing hardware support for enterprises to achieve standardized production and increase production capacity.

In the construction of the service system, the front line intelligent focus on customer demand response and scenario adaptation, through professional technical support and after-sales guarantee, to ensure the stable operation of equipment. In the future, the company will continue to keep up with the development needs of the food industry, increase investment in research and development of intelligent equipment, promote the deep integration of technology and technology, and inject more intelligent power into the high-quality development of the food processing industry.

30+

Distribution of sales regions

100+

Equipment production quantity

3000

Factory Floor Area

news coverage

News information

Leading the Intelligent Innovation of Marinated Flavor Processing Industry

Breakthrough in low-temperature vacuum technology: Reconstructing a new standard for healthy frying "The problems of high oil content and nutrient loss caused by traditional high-temperature frying have become the core bottleneck restricting the development of fried snacks." Front line intelligent research and development director said at the press conference. The new generation production line adopts the self-developed low-temperature vacuum frying system, and the frying temperature is precisely controlled in the range of 80-120 ℃ through the negative pressure environment, which reduces the thermal damage by 40% compared with the traditional equipment. Field measurement data show that the vitamin C retention rate of bean crisp chips produced by this equipment is increased by 50%, and the fat content is reduced from 25% to 15% in the traditional process.

Learn More

12-10

Innovation of Food Equipment Industry Driven by Frontal Intelligence

Breakthrough in low-temperature vacuum technology: Reconstructing a new standard for healthy frying "The problems of high oil content and nutrient loss caused by traditional high-temperature frying have become the core bottleneck restricting the development of fried snacks." Front line intelligent research and development director said at the press conference. The new generation production line adopts the self-developed low-temperature vacuum frying system, and the frying temperature is precisely controlled in the range of 80-120 ℃ through the negative pressure environment, which reduces the thermal damage by 40% compared with the traditional equipment. Field measurement data show that the vitamin C retention rate of bean crisp chips produced by this equipment is increased by 50%, and the fat content is reduced from 25% to 15% in the traditional process.

Learn More

10-20

Fengxing Intelligent Freeze-drying Production Line Put into Production

Breakthrough in low-temperature vacuum technology: Reconstructing a new standard for healthy frying "The problems of high oil content and nutrient loss caused by traditional high-temperature frying have become the core bottleneck restricting the development of fried snacks." Front line intelligent research and development director said at the press conference. The new generation production line adopts the self-developed low-temperature vacuum frying system, and the frying temperature is precisely controlled in the range of 80-120 ℃ through the negative pressure environment, which reduces the thermal damage by 40% compared with the traditional equipment. Field measurement data show that the vitamin C retention rate of bean crisp chips produced by this equipment is increased by 50%, and the fat content is reduced from 25% to 15% in the traditional process.

Learn More

10-20

Front line intelligent enabling food processing clean and efficient upgrade

Breakthrough in low-temperature vacuum technology: Reconstructing a new standard for healthy frying "The problems of high oil content and nutrient loss caused by traditional high-temperature frying have become the core bottleneck restricting the development of fried snacks." Front line intelligent research and development director said at the press conference. The new generation production line adopts the self-developed low-temperature vacuum frying system, and the frying temperature is precisely controlled in the range of 80-120 ℃ through the negative pressure environment, which reduces the thermal damage by 40% compared with the traditional equipment. Field measurement data show that the vitamin C retention rate of bean crisp chips produced by this equipment is increased by 50%, and the fat content is reduced from 25% to 15% in the traditional process.

Learn More

10-17

Feng xing intelligently solves the double problem of efficiency and quality in food freeze-drying industry.

Breakthrough in low-temperature vacuum technology: Reconstructing a new standard for healthy frying "The problems of high oil content and nutrient loss caused by traditional high-temperature frying have become the core bottleneck restricting the development of fried snacks." Front line intelligent research and development director said at the press conference. The new generation production line adopts the self-developed low-temperature vacuum frying system, and the frying temperature is precisely controlled in the range of 80-120 ℃ through the negative pressure environment, which reduces the thermal damage by 40% compared with the traditional equipment. Field measurement data show that the vitamin C retention rate of bean crisp chips produced by this equipment is increased by 50%, and the fat content is reduced from 25% to 15% in the traditional process.

Learn More

01-17

Partner